Fans

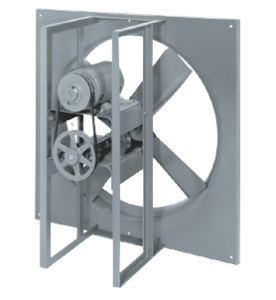

Propeller Fans

An axial fan has the form a cylindrical-cased wheel with the impeller fixed to a bushing at some angle to rotation plane. As the impeller blades rotate air is trapped betwen and is moved further axially. Air is hardly moved in the radial direction. The axial fan blades are mostly set directly on the motor shaft.

Propeller Fans >>

Belt Drive Propeller Fans

Each Canada Blower fan housing is continuously welded for sturdy construction. Only rugged duty cast iron housed bearings are installed in the blower. Shafts of nonsulpharized carbon steel are precisely turned, ground and polished for a precision fit.

Belt Drive Propeller Fans >>

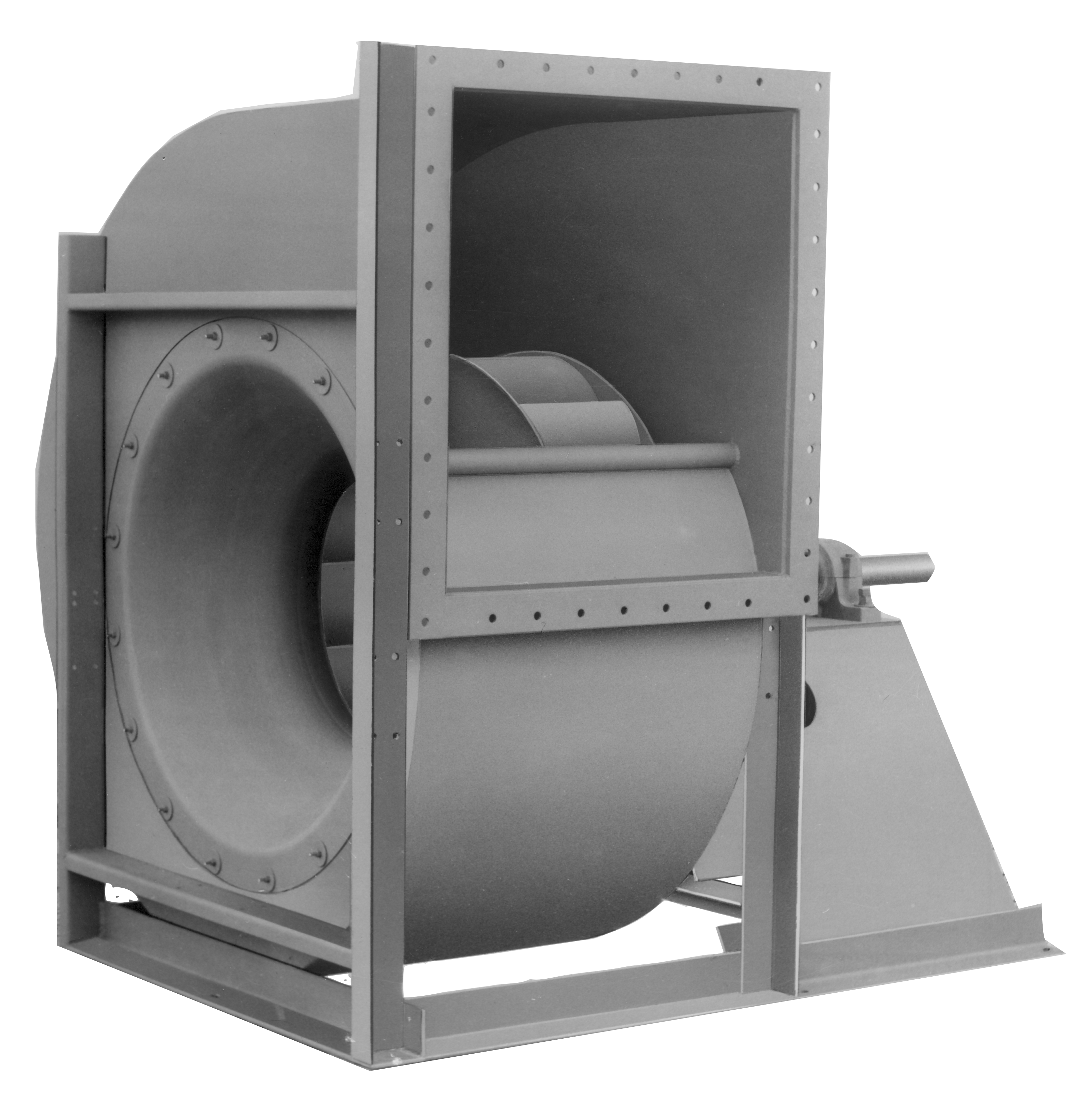

Industrial Fans

The forward curve fans are designed with a heavy-duty housing and base. Canada Blower wheels are dynamically balanced and supplied with cast iron hubs. All fans are available in either clockwise or counterclockwise rotation and the housings are rotatable up to 8 different positions.

Industrial Fans >>

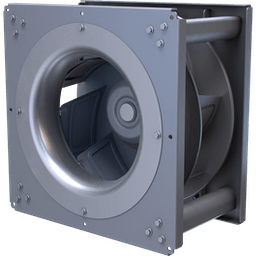

Plenum Fans

Each Canada Blower housing is continuously welded for sturdy construction. Only rugged duty cast iron housed bearings are installed in the blower. Shafts of nonsulpharized carbon steel are precisely turned, ground and polished for a precision fit.

Plenum Fans >>

Plug Pak Fans

Canada Blower propeller fans are constructed with an integral motor-fan guard mounted on a steel panel. The propellers have aluminum bases with steel hubs. All fans come with totally enclosed motors.

Plug Pak Fans >>

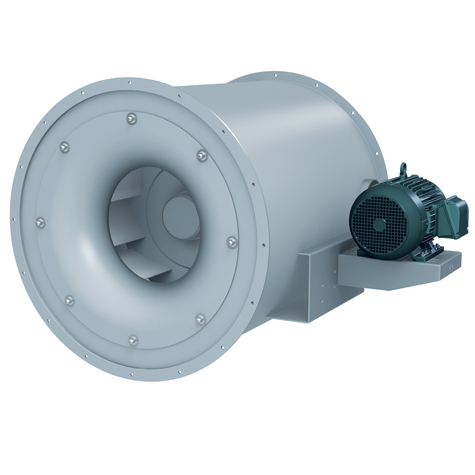

Inline Centrifugal Fans

Each blower housing is continuously welded for sturdy construction. Only rugged duty cast iron housed bearings are installed in the blower. Shafts of nonsulpharized carbon steel are precisely turned, ground and polished for a precision fit.

Inline Centrifugal Fans >>

Centrifugal Power Fixed Fans

The propeller fans are constructed with an integral motor-fan guard mounted on a steel panel. The propellers have aluminum bases with steel hubs. All fans come with totally enclosed motors.

centrifugal-blowers-powerfoil_img_4.jpg Centrifugal Power Fixed Fans >>

Centrifugal Power Foil Fans

Canada Blower forward curve fans are designed with a heavy-duty housing and base. The wheels are dynamically balanced and supplied with cast iron hubs. All fans are available in either clockwise or counterclockwise rotation and the housings are rotatable up to 8 different positions.

Centrifugal Power Foil Fans >>

Contact NIS-CO today to find out more about our full line of world class backward inclined blowers to meet all of your industrial blower fan needs. Our backward inclined blowers are used in both commercial and industrial applications and are used all over Canada and the United States. Our Industrial Blowers and Large Industrial Fans come in both Direct Drive Blower and Belt Drive Blower configurations. You can also choose between forward curve blowers and backward inclined blowers, depending on your needs. We also carry a range of centrifugal blower fans which are high rated and high temperature blowers. We also carry a wide range of propeller fans, plenum fans, large industrial fans which can come in both belt drive and direct drive configurations.

Contact Canada Fans today to find out more about our full line of world class backward inclined blowers to meet all of your industrial blower fan needs. Our backward inclined blowers are used in both commercial and industrial applications and are used all over Canada and the United States. Our Industrial Blowers and Large Industrial Fans come in both Direct Drive Blower and Belt Drive Blower configurations. You can also choose between forward curve blowers and backward inclined blowers, depending on your needs. We also carry a range of centrifugal blower fans which are high rated and high temperature blowers. We also carry a wide range of propeller fans, plenum fans, large industrial fans which can come in both belt drive and direct drive configurations.

NIS-CO offers a full line of the following Industrial Blower Fan Products:

Tags: Backward Inclined Blowers, Backward Inclined Direct Drive Blower, Belt Drive Blower, Belt Drive Propeller Fans, Blower Fan Suppliers, Centrifugal Blower Fan, Centrifugal Power Fixed Fan, Centrifugal Power Foil Fan, Direct Drive Blower, Forward Curve Belt Drive Blower, Forward Curve Blower, High Temperature Blower, Industrial Blower, Industrial Blower Manufacturer, Industrial Blower Suppliers, Industrial Centrifugal Blower, Industrial Fans and Blowers, Industrial Pressure Blower, Inline Centrifugal Fans, Large Industrial Fan, Plenum Fans, Plug Pak Fans, Propeller Fans, Radial Blade Belt Drive Blowers, Radial Blade Blower, Radial Blade Direct Drive Blowers, Belt Drive Fans, Belt Drive Industrial Fans, Belt Drive Industrial Blowers, Belt Drive Blower Fan, Industrial Large Fans, Industrial Blowers Centrifugal, Industrial Direct Drive Radial Blowers, Large Industrial Blowers, Blower High Temperature, Fans Plenum, Industrial Plenum Fans, Plenum Fan Suppliers, Plenum Fan Manufacturer, Belt Drive Fan Suppliers, Belt Drive Fan Manufacturer, Industrial Centrifugal Blower Supplier, Centrifugal Blower Fan Manufacturer, Propeller Fan Suppliers, Propeller Fan Manufacturer, Belt Drive Radial Blower Supplier, Direct Drive Blower Supplier, Belt Drive Blower Manufacturer, High Temperature Blower Suppliers, High Pressure Blower Supplier, Suppliers Centrifugal Fans, Manufacturers Centrifugal Fans, Centrifugal Industrial Power Fixed, Centrifugal Power Fixed, Centrifugal Power Foil, Industrial Centrifugal Power Fixed, Industrial Forward Curve Blower, Forward Curve Industrial Blower, Forward Curve Blower Supplier, Forward Curve Blower Manufacturer