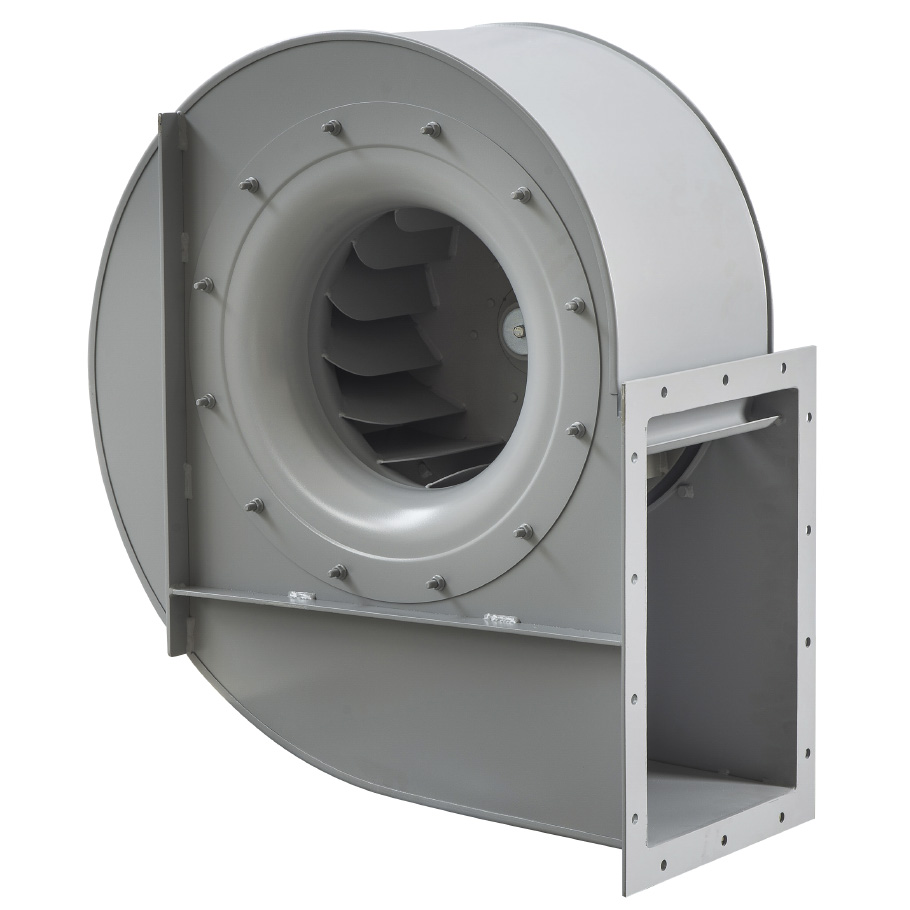

NIS-CO BLOWERS “Acoustafoil” Centrifugal Power Fixed Fan NON-OVERLOADING BLOWERS

CERTIFIED PERFORMANCE RATING Centrifugal Power Fixed Fan

NIS-CO Centrifugal Power Fixed Fan Blowers/Madison Manufacturing Co. certifies that the “Acoustafoil” Canada Blower single width, single inlet blowers shown herein on pages 6-23 are licensed to bear the AMCA Seal. The ratings shown are based on tests and procedures performed in accordance with AMCA Publication 211 and comply with the requirements of the AMCA Certified Ratings Program ventilating.com fanblower.com highpressureblower.net industrialblowerfan.com industrialfanblower.net industrialfanblower.com pressureblower.net industrialpressureblower.com tenderall.com chicagoblowercanada.com cbblower.com buffaloblower.com buffalofan.com nis-co.com canadianblower.com olegsystems.com canadablower.com abbblower.com acmefan.net industrialblower.net fansandblowers.net americanblower.net barryfan.com cincinnatifan.net canadafans.com barryfan.net Canada Blower industrial fans are designed for a variety of airflow volumes and pressure combinations. Canada Blower industrial duty centrifugal fans and blowers satisfy a wide range of application requirements: Airfoil Fans Backward Curved Fans Backward Inclined Fans High Pressure Radial Shrouded Fans High Pressure Radial Open Fans Industrial Exhauster Fans Top Mount Fans.

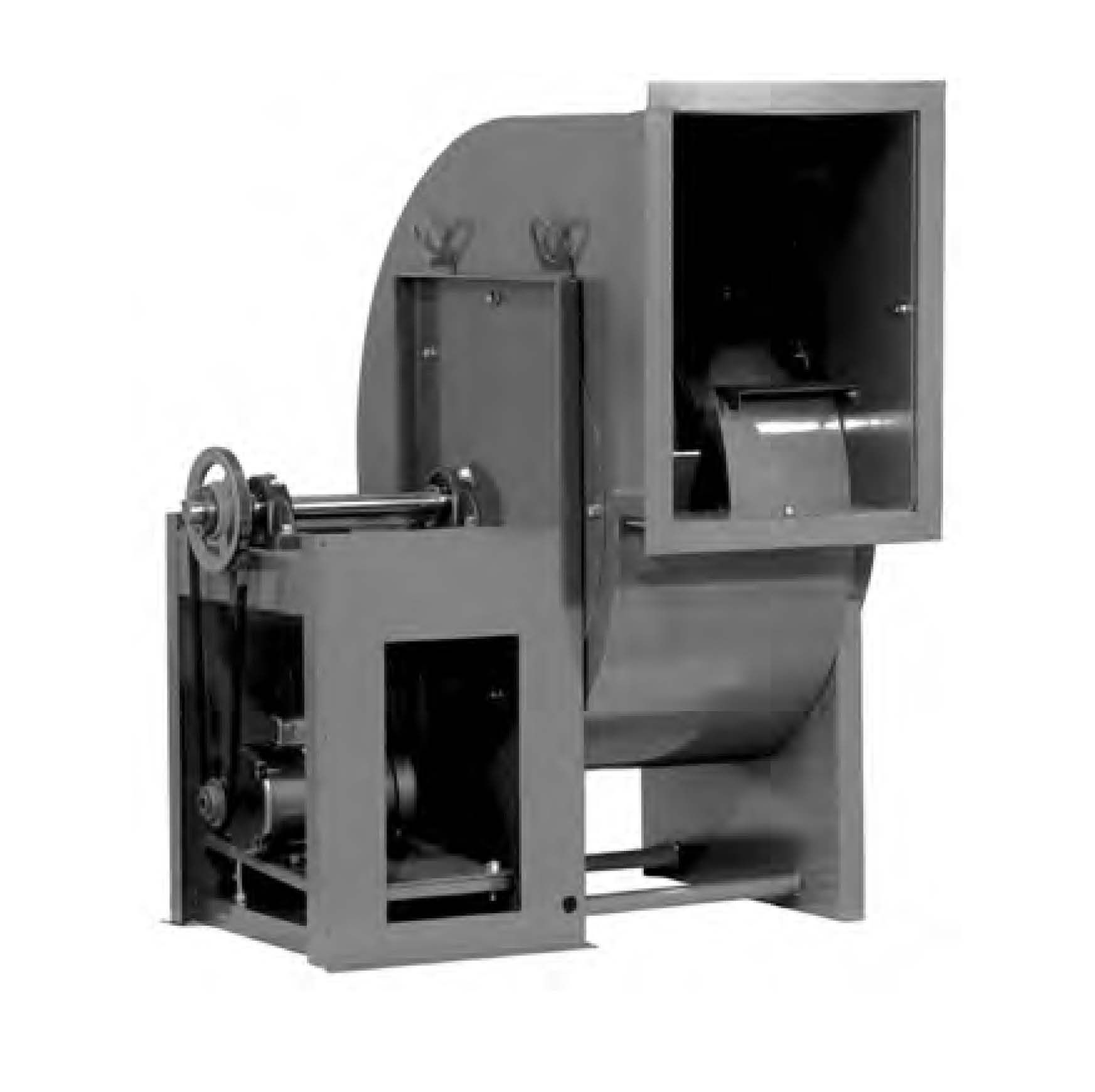

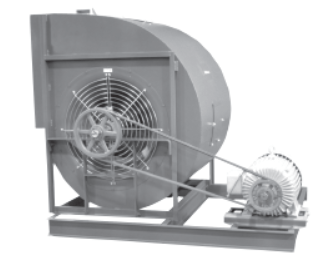

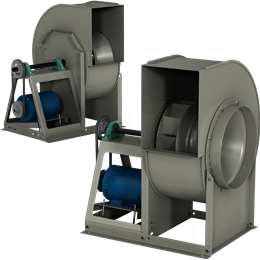

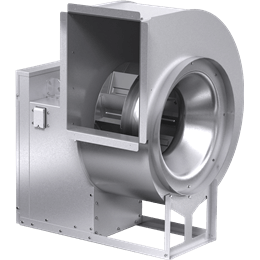

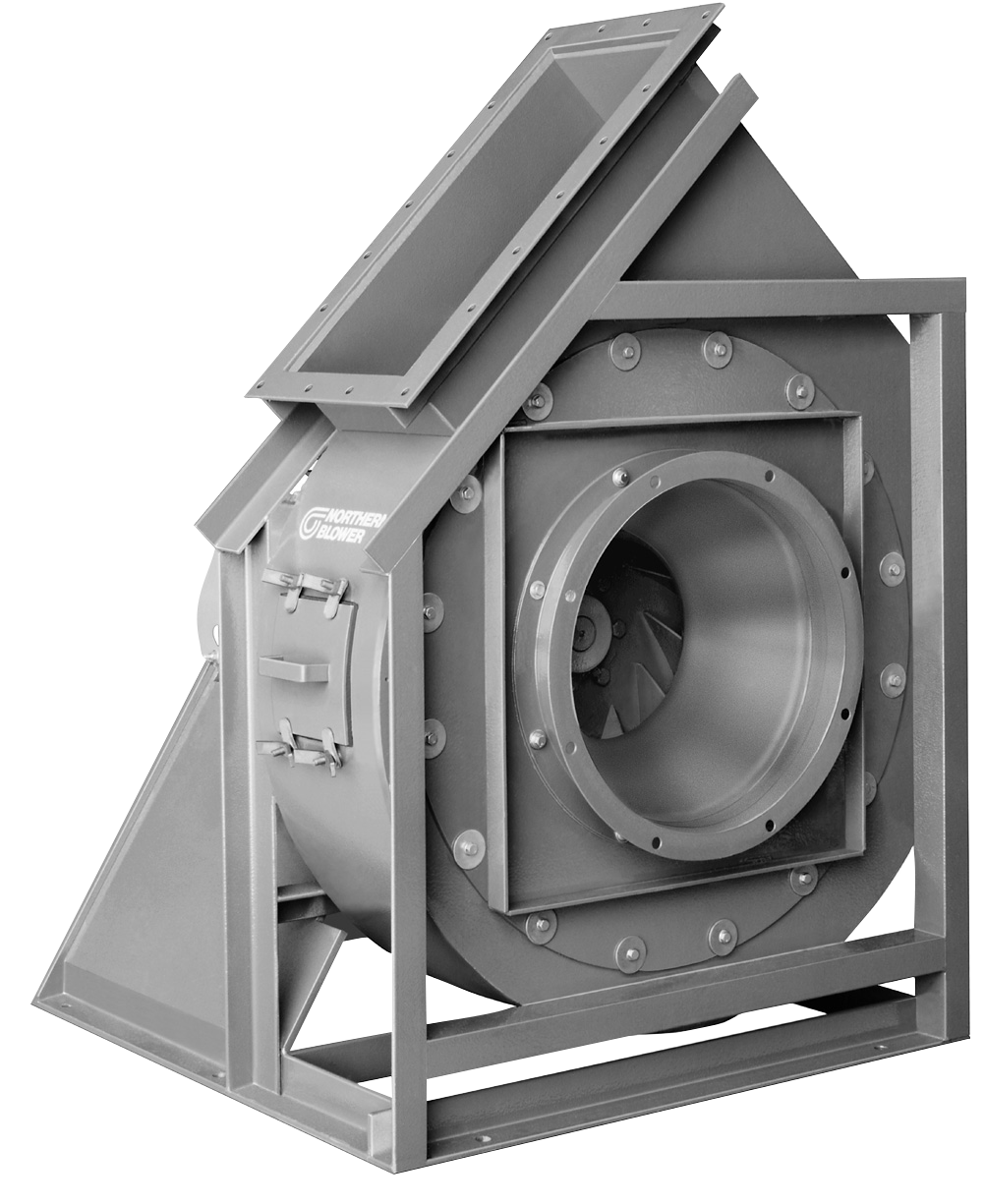

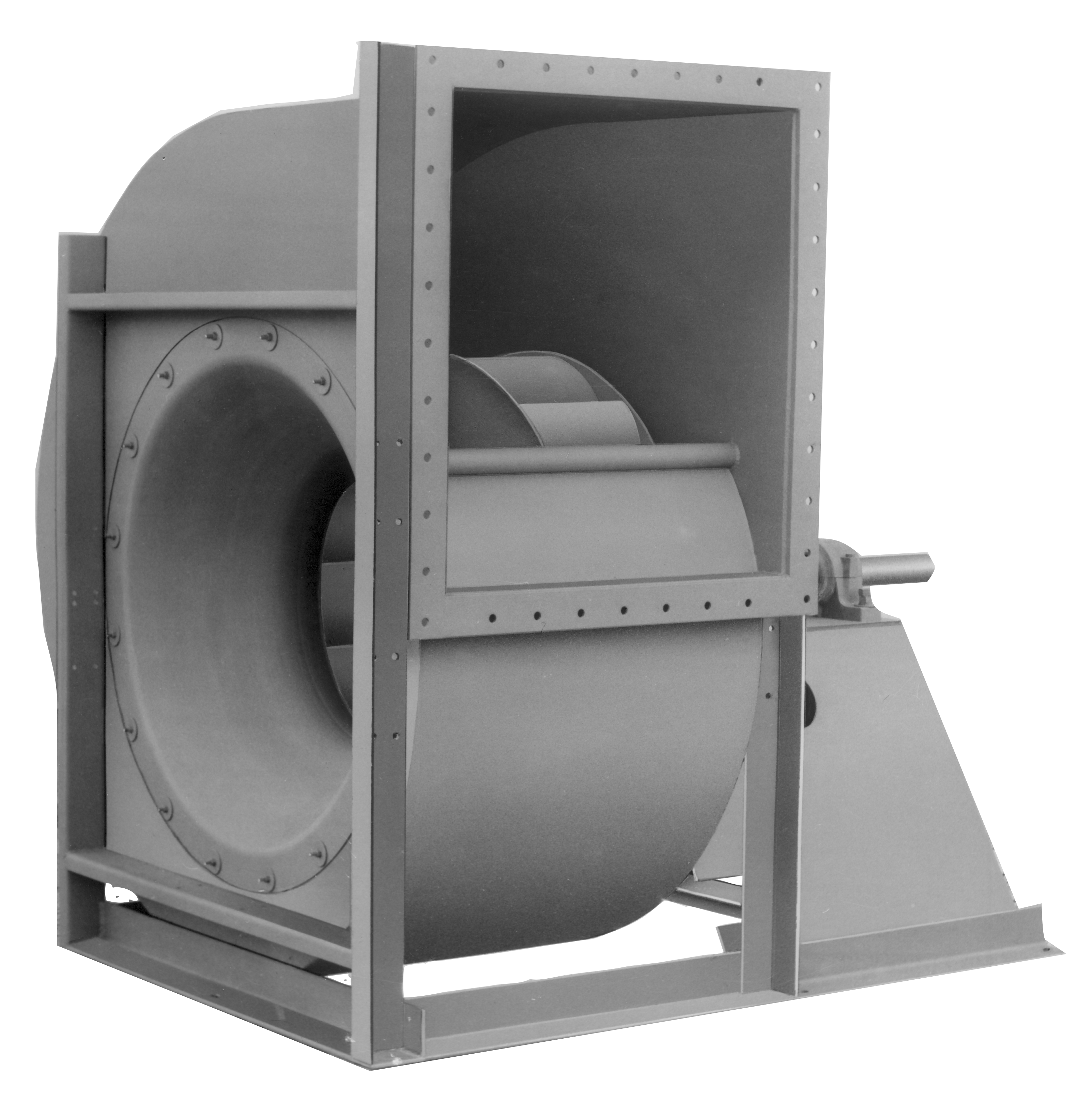

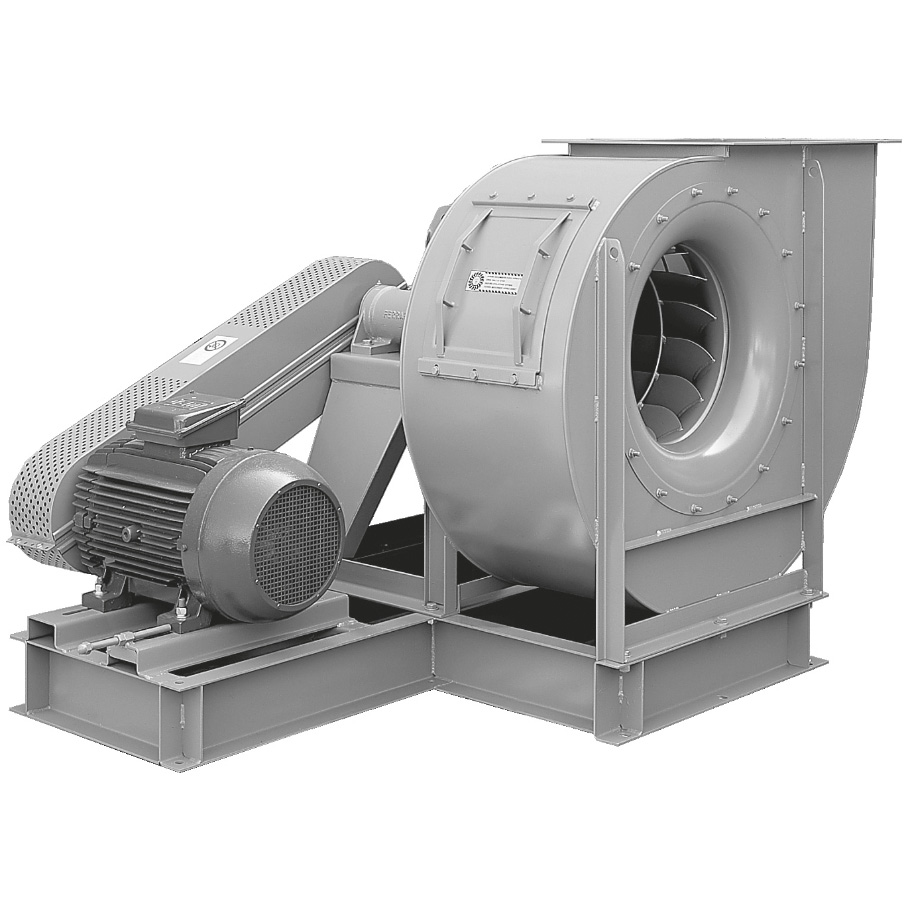

The NIS-CO Centrifugal Power Fixed Fan Blowers “Acoustafoil” non-overloading blower is built for the many applications required by both commercial and industrial users. The backwardly inclined flat blade construction produces a high efficiency blower ideal for medium and high pressure applications. This highly efficient design provides for extremely quiet operation.

Each Centrifugal Power Fixed Fan blower housing is continuously welded for sturdy construction. Only rugged duty cast iron housed bearings are installed in the “Acoustafoil” blower. Shafts of nonsulpharized carbon steel are precisely turned, ground and polished for a precision fit. Each wheel is statically and dynamically balanced for optimum trouble-free performance and longevity. The “Acoustafoil” non-overloading blower is built with dependability and minimum maintenance in mind.

Wheel sizes run from 10-1/2" thru 24-1/2" for struction classes. Our many accessories and arrangements allow for various individualized applications.

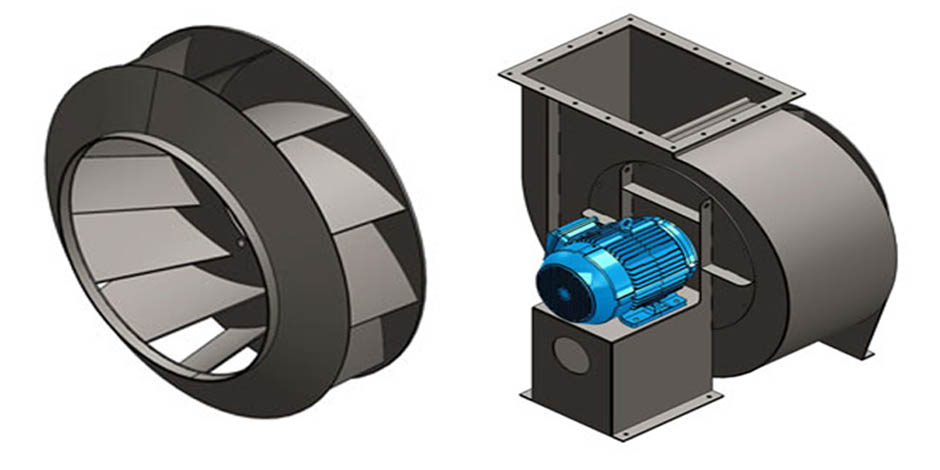

Acoustafoil WHEELS

Wheels in Centrifugal Power Fixed Fan Acoustafoil blowers are of a new advanced design for high static efficiency an dlow noise level operation. The blades are die cut and are arc welded in special fixtures to a true aerodynamically shaped spun cone. Hubs of streamlined design are heavy cast iron with accurately machined bore and keyway. Back of hub is machined to fit concentrically with back plate. Hub is riveted to back plate by heavy duty hydraulic riveters. The wheel assembly, when finished, becomes a perfect one-piece construction ready for years of quiet and efficient air moving.

WHEEL WEIGHTS AND WR IN lBS. FT.

STATIC AND DYNAMIC BALANCING

Completed Centrifugal Power Fixed Fan wheel assemblies of all sizes are statically and dynamically balanced on electronically controlled balancing machines. The necessary weights are arc welded into place so that the wheel will always stay in balance.

After the complete Centrifugal Power Fixed Fan blowers are assembled, they are all given a running-in inspection and again examined for balance by a portable electronic balancing unit. Inspectors add balance weights to the wheel if necessary to pass a very rigid design requirement

| Fan Size |

|

SWSI |

|

DWDI |

|

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Class I |

|

Class II |

|

Class I |

|

Class II |

|

||||||

|

|

Weight |

|

WR2 | Weight |

|

WR2 | Weight |

|

WR2 | Weight |

|

WR2 | |

| BI105 | 12.7 |

|

.92 |

|

15.1 |

|

.93 | – |

|

– | – |

|

– |

| BI122 | 20.2 |

|

1.9 |

|

24.3 |

|

2.7 | 27.7 |

|

3.2 | 36 |

|

4.3 |

| BI135 | 23.4 |

|

2.9 |

|

28.4 |

|

3.9 | 32.8 |

|

4.4 | 45.6 |

|

6.4 |

| BI150 | 27.5 |

|

4.3 |

|

33.6 |

|

5.7 | 42.3 |

|

7 | 75.4 |

|

10.4 |

| BI165 | 35 |

|

6.9 |

|

42.3 |

|

8.3 | 74.3 |

|

12 | 84.8 |

|

14.6 |

| BI182 | 41 |

|

10.5 |

|

49.6 |

|

12.6 | 84.6 |

|

17.5 | 97.4 |

|

21.3 |

| BI200 | 56.5 |

|

17 |

|

56.4 |

|

17.4 | 111.4 |

|

30.3 | 111.4 |

|

30.3 |

| BI222 | 67.5 |

|

22.9 |

|

60.3 |

|

23 | 130.6 |

|

45.6 | 115 |

|

38.3 |

| BI245 | 80.5 |

|

38.4 |

|

77.6 |

|

34.2 | 152.6 |

|

66.7 | 135 |

|

56.8 |

CENTRIFUGAL POWER FIXED FAN - POWER FIXED DUCT TYPE INLET VANE CORRECTIONS FOR SINGLE WIDTH AND DOUBLE WIDTH UNITS

The ducted inlet vane corrections for BI centrifugal blowers are with the vanes fully open.

Due to additional losses at the fan inlet caused by the installation of variable inlet vanes, a slight correction above catalog RPM and BHP ratings is necessary to reach design perfor

mance.

Correction Factors:

Design RPM x 1.03 Design BHP x 1.08

Example:

BI245 SWSI, Class I is to operate at 6570 CFM at 3î S.P.

Step 1: CENTRIFUGAL POWER FIXED FAN - Through interpolation, establish the design RPM and BHP of the unit from the performance tables for this unit it would be 1177 RPM and 4.39 BHP.

Step 2: Multiply design RPM and BHP by the correction factors to determine the required RPM and BHP for a fan with ducted type inlet vanes

STANDARDS ADOPTED FOR SPARK-RESISTANT FANS AMCA STANDARD 99-0401-86 - CENTRIFUGAL POWER FIXED FAN

Spark Resistant – Type A:

AMCA Standards require that all parts of the fan in contact with the air or gas being handled shall be made of non-ferrous material.

Spark Resistant – Type B:

AMCA Standards require the fan to have the wheel and ring about the opening through which the shaft passes of nonferrous material. Ferrous hubs, shafts and hardware are permitted. Fans for this condition are furnished with a non-ferrous wheel (except hub and hardware) and a non-ferrous rubbing plate or non-ferrous shaft seal around the shaft opening

Spark Resistant – Type C:

AMCA Standards require the fan to be so constructed that a shift of the wheel or shaft will not permit two ferrous parts of the fan to rub or strike. Fans for this condition will be furnished with a nonferrous inlet cone and rubbing plate around the shaft opening.

NOTE:ᆳ ᆳ ᆳ ᆳ ᆳtant fans, the user shall electrically ground all fan parts. Bearings shall not be placed in the air or gas stream. A non-ferrous material shall be any material with less than 5% iron on any other material with demonstrated ability to be spark resistant

Example:

1177 (Design RPM) x 1.03 = 1212 (Corrected RPM)

4.39 (Design BHP) x 1.08 =

4.74 (Corrected BHP)

Fan Selection:

BI245 SWSI, Class I to deliver 6570 CFM at 3" S.P. with duct type inlet vanes requires 1212 RPM and 4.74 BHP

Caution:Check RPM and BHP to insure they do not exceed selected blower

class or motor horsepower

The use of these constructions in no way implies a guarantee of safety for any level of spark resistance. Spark resistant construction does not protect against ignition of explosive gases caused by catastrophic failure or from any airstream material that may be present in a system.

Sparkproof construction available for SWSI units in arrangements 1,2,8,9, and 10 only

NIS-CO BLOWERS “Acoustafoil” NON-OVERLOADING BLOWERS

MATERIAL SPECIFICATIONS - CENTRIFUGAL POWER FIXED FANS

| M o de l N o. | C la s s | S h aft D ia m e t e r | H o u s in g G a u g e s | F r am e G au g e s | DW DI | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| SW SI | D W D I | Ba n d F a c e | SW SI | |||||||

| Br g . a n d W h e e l Ar g ' t. 1 , 8 & 9 | Ar g ' t. 3 & 7 | S W S I | DW DI | S W D I DW D I | D r iv e S id e | In le t S id e | ||||

| Br g . | W h e el | |||||||||

| BI1 0 5 | 1 2 | 3/4 1 | -- | -- | 2 0 2 0 | -- | 16 1 6 | 16 1 6 | -- | -- |

| B I12 2 | 1 2 | 1 1 -3/16 | 1 -3 /1 6 1-7/16 | 1 -3 /1 6 1 -7/1 6 | 1 6 1 6 | 1 6 14 | 1 6 16 | 1 4 14 | 1 6 16 | 1 4 14 |

| B I13 5 | 1 2 | 1 1 -3/16 | 1 -3 /1 6 1-7/16 | 1 -7 /1 6 1-11/16 | 1 6 1 6 | 1 4 14 | 1 4 14 | 1 4 14 | 1 6 16 | 1 4 14 |

| B I15 0 | 1 2 | 1 1 -3/16 | 1 -7 /1 6 1-11/1 6 | 1 -7 /1 6 1-15/16 | 1 6 1 6 | 1 4 14 | 1 4 14 | 1 4 14 | 1 6 16 | 1 4 14 |

| B I16 5 | 1 2 | 1 1 -3/16 | 1 -7 /1 6 1-15/1 6 | 1 -11/16 1-15/16 | 1 6 1 6 | 14 14 | 14 14 | 14 14 | 16 16 | 14 14 |

| B I18 2 | 1 2 | 1 -3/16 1 -7/16 | 1 -11/1 6 1-15/1 6 | 1-11/16 1-15/16 | 1 6 1 6 | 14 14 | 14 14 | 14 14 | 14 14 | 14 14 |

| B I20 0 | 1 2 | 1 -3/16 1 -7/16 | 1 -11/1 6 2-3/16 | 1-15/16 2 -3/1 6 | 1 4 1 4 | 14 14 | 14 14 | 12 12 | 14 14 | 12 12 |

| B I22 2 | 1 2 | 1 -3/16 1-1 1 /1 6 | 1 -15/1 6 2-3/16 | 1-15/16 2 -3/1 6 | 1 4 1 4 | 14 14 | 12 12 | 12 12 | 14 14 | 12 12 |

| B I24 5 | 1 2 | 1 -7/16 1-1 1 /1 6 | 1 -15/1 6 2-7/16 | 2 -3/1 6 2 -7/1 6 | 1 4 1 4 | 14 14 | 12 12 | 12 12 | 12 12 | 12 12 |

HEAVY DUTY ANTI-FRICTION BEARINGS - CENTRIFUGAL POWER FIXED FANS

Acoustafoil blowers are equipped with self-aligning single row ball bearings pillow blocks.

Computerized selections have been made on all bearings based on radial, thrust and combined loads to give 100,000 average life hours (AFBMA L50) at the maximum design of each blower class. Bearings selected have effective seals to retain the lubricant an dto prevent contamination. All have grease fittings for

relubrication The Centrifugal Power Fixed Fan table shows the type of bearings used for each unit. NIS-CO Blowers / Madison Manufacturing Co. reserves the right to change bearings of equal ratings.

A-Normal Duty Self-Aligning Ball Bearing Pillow Block with Single Locking Collar - Centrifugal Power Fixed Fan

B-Normal Duty C-Medium Duty Self-Alining Ball Baearings Pillow Block with Double Locking Collars - Centrifugal Power Fixed Fan

| Model No. | Arrangement 1, 8 & 9 SWSI Bearing | Arrangement 3 & 7 DWDI B earing | ||

|---|---|---|---|---|

|

|

Class I | Class II | Class I | Class II |

| BI105 BI122 BI135 BI150 BI165 BI182 BI200 BI222 BI245 | A A A A A A A A A | A A A A A A A B B | -A A A A A A A A | -A C C C C C C C |

| Temperature Operating Limits Temperature RPM Derating Factors in Percent (Centrifugal Power Fixed Fan): | |

|---|---|

| 300oF 100% 301-400oF 96% 401-500oF 92% 501-600oF 85% Steel Wheel | 150oF 100% 151-200oF 95% 201-250oF 80% Aluminum Wheel |

CENTRIFUGAL POWER FIXED FAN TABLES

4 4 4 4 4

Radial Inlet Vanes: Duct type inlet vanes

Quick Opening Type

5 5

NIS-CO BLOWERS “Acoustafoil” Centrifugal Power Fixed Fan PERFORMANCE TABLES

BI105-1 TIP SPEED(FPM)=2.749xRPM OUTLET(.636Sq.Ft. Inside) MAX.HP=.0387(RPM/1000)3 11 3/4"x8" Outside

SINGLE-WIDTH MAX.RPM

WHEEL DIAMETER=10 1/2 INLET (.894 Sq.Ft. Inside) CL.1 3623

CL.2 4724

12 7/8"Dia. Outside

CL.3 5961

| VOL CFM | VEL FPM | .25SP | .5SP | .75 SP | 1 SP | 1.25 SP | 1.5 SP | 2SP | 2.5 SP | 3SP | 3.5 SP | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | ||

| 509 572 636 | 800 900 1000 | 965 1034 1106 | 0.03 0.04 0.05 | 1177 1227 1283 | 0.06 0.07 0.08 | 1369 1407 1451 | 0.09 0.10 0.11 | 1545 1574 1609 | 0.13 0.14 0.15 | 1709 1729 1757 | 0.16 0.18 0.19 | -1876 1898 | -0.22 0.23 | --2159 | --0.33 | --- | --- | --- | --- | --- | --- |

| 700 763 827 | 1100 1200 1300 | 1183 1261 1342 | 0.06 0.07 0.09 | 1345 1411 1481 | 0.09 0.11 0.12 | 1502 1557 1618 | 0.13 0.14 0.16 | 1651 1698 1750 | 0.17 0.18 0.20 | 1792 1832 1878 | 0.21 0.23 0.25 | 1926 1961 2001 | 0.25 0.27 0.29 | 2178 2204 2234 | 0.35 0.37 0.40 | 2412 2429 2452 | 0.46 0.48 0.51 | -2641 2658 | -0.60 0.62 | --2853 | --0.75 |

| 890 954 1018 | 1400 1500 1600 | 1425 1509 1594 | 0.10 0.12 0.14 | 1554 1629 1707 | 0.14 0.16 0.18 | 1682 1749 1820 | 0.18 0.20 0.23 | 1807 1867 1931 | 0.23 0.25 0.28 | 1928 1982 2040 | 0.27 0.30 0.33 | 2046 2095 2148 | 0.32 0.35 0.38 | 2270 2310 2354 | 0.42 0.45 0.49 | 2481 2514 2551 | 0.54 0.57 0.60 | 2680 2707 2739 | 0.66 0.69 0.73 | 2870 2892 2919 | 0.79 0.82 0.86 |

| 1081 1145 1208 | 1700 1800 1900 | 1681 1768 1856 | 0.17 0.19 0.22 | 1786 1867 1949 | 0.21 0.23 0.27 | 1892 1967 2044 | 0.25 0.28 0.32 | 1998 2067 2139 | 0.30 0.34 0.37 | 2102 2166 2233 | 0.36 0.39 0.43 | 2204 2264 2326 | 0.41 0.45 0.48 | 2403 2454 2509 | 0.52 0.56 0.60 | 2593 2637 2686 | 0.64 0.68 0.73 | 2774 2814 2857 | 0.77 0.82 0.86 | 2949 2983 3021 | 0.91 0.95 1.00 |

| 1272 1336 1399 | 2000 2100 2200 | 1945 2033 2121 | 0.25 0.29 0.33 | 2032 2116 2201 | 0.30 0.34 0.38 | 2122 2202 2283 | 0.35 0.39 0.43 | 2213 2288 2365 | 0.41 0.45 0.49 | 2302 2374 2447 | 0.46 0.51 0.55 | 2391 2459 2529 | 0.52 0.57 0.61 | 2657 2627 2690 | 0.65 0.70 0.75 | 2737 2792 2849 | 0.78 0.83 0.89 | 2903 2952 3003 | 0.91 0.97 1.03 | 3063 3107 3154 | 1.06 1.12 1.18 |

| 1463 1526 1654 | 2300 2400 2600 | 2210 2298 2475 | 0.37 0.41 0.51 | 2287 2373 2548 | 0.42 0.47 0.57 | 2365 2447 2615 | 0.47 0.52 0.63 | 2443 2523 2685 | 0.53 0.58 0.70 | 2522 2598 2754 | 0.60 0.65 0.76 | 2600 2673 2824 | 0.66 0.72 0.84 | 2755 2822 2962 | 0.80 0.86 0.98 | 2908 2970 3099 | 0.94 1.01 1.14 | 3058 3115 3235 | 1.09 1.16 1.30 | 3204 3257 3369 | 1.24 1.31 1.46 |

| 1781 1908 2035 | 2800 3000 3200 | 2655 2841 3027 | 0.63 0.77 0.93 | 2725 2902 3078 | 0.70 0.84 0.99 | 2786 2960 3135 | 0.76 0.90 1.07 | 2850 3018 3189 | 0.82 0.97 1.14 | 2915 3078 3244 | 0.90 1.05 1.21 | 2979 3138 3301 | 0.97 1.12 1.29 | 3108 3259 3414 | 1.13 1.28 1.46 | 3236 3379 3527 | 1.29 1.46 1.64 | 3363 3498 3639 | 1.46 1.63 1.82 | 3489 3617 3751 | 1.63 1.81 2.01 |

| 2162 VOL CFM 1208 | 3400 VEL FPM 1900 | 3200 | 1.09 | 3255 | 1.17 | 3311 | 1.25 | 3362 | 1.32 | 3413 | 1.40 | 3466 | 1.49 | 3573 | 1.66 | 3679 | 1.84 | 3785 | 2.04 | 3890 | 2.23 |

| 4SP | 4.5 SP | 5SP | 5.5 SP | 6SP | 6.5 SP | 7SP | 7.5 SP | 8SP | 8.5 SP | ||||||||||||

| RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | ||

| 3181 | 1.15 | 3335 | 1.31 | 3485 | 1.47 | 3630 | 1.63 | 3772 | 1.81 | 3910 | 1.98 | 4045 | 2.17 | 4176 | 2.36 | - | - | - | - | ||

| 1272 1336 1399 | 2000 2100 2200 | 3218 3258 3301 | 1.21 1.27 1.33 | 3368 3405 3444 | 1.36 1.43 1.50 | 3415 3548 3584 | 1.53 1.59 1.66 | 3657 3687 3720 | 1.70 1.76 1.84 | 3796 3823 3853 | 1.87 1.94 2.01 | 3931 3955 3983 | 2.05 2.12 2.20 | 4063 4085 4110 | 2.24 2.31 2.39 | 4192 4212 4235 | 2.43 2.50 2.58 | 4319 4336 4357 | 2.63 2.70 2.78 | 4443 4458 4477 | 2.83 2.91 2.99 |

| 1463 1526 1654 | 2300 2400 2600 | 3347 3396 3500 | 1.40 1.47 1.63 | 3487 3532 | 1.57 1.64 | 3623 3665 | 1.74 1.81 | 3756 | 1.91 | 3886 | 2.09 | 4013 | 2.28 | 4138 | 2.47 | 4261 | 2.67 | 4380 | 2.87 | 4498 | 3.08 |

| 3795 | 1.99 | 3922 | 2.18 | 4047 | 2.37 | 4169 | 2.56 | 4289 | 2.76 | 4407 | 2.96 | 4523 | 3.17 | ||||||||

| 3629 | 1.81 | 3756 | 1.98 | 3880 | 2.17 | 4002 | 2.36 | 4122 | 2.55 | 4239 | 2.75 | 4355 | 2.96 | 4468 | 3.16 | 4580 | 3.38 | ||||

| 1781 1908 2035 | 2800 3000 3200 | 3613 3734 3862 | 1.81 2.00 2.21 | 3736 | 1.99 | 3856 | 2.17 | 3975 | 2.36 | 4091 | 2.56 | 4206 | 2.76 | 4319 | 2.96 | 4430 | 3.17 | 4540 | 3.39 | 4647 | 3.60 |

| 3850 3972 | 2.19 2.41 | 3965 4081 | 2.38 2.61 | 4078 4189 | 2.58 2.81 | 4189 4295 | 2.78 3.02 | 4299 4401 | 2.98 3.23 | 4408 4505 | 3.19 3.45 | 4515 4607 | 3.41 3.67 | 4620 4709 | 3.63 3.89 | 4724 4809 | 3.85 4.12 | ||||

| 2162 2290 2417 | 3400 3600 3800 | 3995 4134 4278 | 2.44 2.68 2.95 | 4100 4234 4372 | 2.64 2.90 3.18 | 4204 4332 4466 | 2.85 3.12 3.40 | 4306 4430 4560 | 3.06 3.34 3.63 | 4408 4528 4653 | 3.28 3.56 3.87 | 4509 4624 4745 | 3.50 3.79 4.10 | 4609 4720 4837 | 3.72 4.02 4.34 | 4708 4815 4928 | 3.95 4.25 4.58 | 4805 4908 5018 | 4.18 4.49 4.83 | 4902 5001 5108 | 4.41 4.73 5.08 |

| 2544 2671 2798 | 4000 4200 4400 | 4425 4576 4730 | 3.24 3.56 3.91 | 4515 4662 4812 | 3.48 3.80 4.15 | 4605 4748 4894 | 3.71 4.04 4.40 | 4694 4833 4976 | 3.95 4.29 4.65 | 4783 4918 5057 | 4.19 4.54 4.91 | 4871 5003 5138 | 4.44 4.79 5.17 | 4959 5087 5219 | 4.68 5.05 5.44 | 5047 5171 5300 | 4.93 5.31 5.71 | 5134 5254 5380 | 5.19 5.57 5.98 | 5220 5337 5460 | 5.44 5.83 6.25 |

| 2926 3053 3180 | 4600 4800 5000 | 4887 5046 5207 | 4.28 4.68 5.11 | 4965 5121 5279 | 4.53 4.94 5.37 | 5044 5196 5351 | 4.78 5.20 5.64 | 5122 5271 5424 | 5.05 5.47 5.92 | 5200 5346 5496 | 5.31 5.74 6.20 | 5278 5421 5568 | 5.58 6.02 6.48 | 5356 5496 5639 | 5.85 6.30 6.77 | 5433 5570 5711 | 6.13 6.58 7.06 | 5510 5645 5783 | 6.41 6.87 7.36 | 5587 5719 5854 | 6.69 7.16 7.66 |

| 3307 3434 | 5200 5400 | 5369 5534 | 5.57 6.07 | 5439 5601 | 5.84 6.34 | 5509 5668 | 6.12 6.63 | 5578 5735 | 6.40 6.91 | 5648 5802 | 6.68 7.21 | 5717 5869 | 6.98 7.50 | 5786 5935 | 7.27 7.81 | 5855 6002 | 7.57 8.11 | 5924 6069 | 7.88 8.42 | 5993 6135 | 8.18 8.74 |

| VOL CFM | VEL FPM | 9SP | 9.5 SP | 10 SP | 10.5 SP | 11 SP | 11.5 SP | 12 SP | 12.5 SP | 13 SP | 13.5 SP | ||||||||||

| RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | ||

| 1908 2035 | 3000 3200 | 4827 4908 | 4.08 4.35 | 4928 5006 | 4.31 4.59 | 5028 5102 | 4.55 4.83 | 5126 5198 | 4.79 5.08 | 5224 5292 | 5.03 5.33 | 5320 5386 | 5.28 5.58 | 5415 5478 | 5.53 5.84 | 5509 5569 | 5.79 6.10 | 5602 5659 | 6.05 6.36 | 5693 5749 | 6.31 6.63 |

| 2162 2290 2417 | 3400 3600 3800 | 4997 5094 5196 | 4.65 4.98 5.33 | 5092 5185 5284 | 4.90 5.23 5.58 | 5185 5275 5372 | 5.14 5.48 5.84 | 5277 5364 5458 | 5.39 5.73 6.10 | 5369 5453 5544 | 5.65 5.99 6.37 | 5459 5541 5629 | 5.91 6.26 6.64 | 5549 5627 5713 | 6.17 6.52 6.91 | 5637 5713 5796 | 6.43 6.80 7.18 | 5725 5799 5879 | 6.70 7.07 7.46 | 5812 5883 5961 | 6.98 7.35 7.75 |

| 2544 2671 2798 | 4000 4200 4400 | 5305 5420 5540 | 5.70 6.10 6.53 | 5390 5502 5619 | 5.96 6.37 6.80 | 5475 5583 5697 | 6.23 6.64 7.08 | 5558 5664 5775 | 6.50 6.92 7.37 | 5641 5744 5853 | 6.77 7.19 7.65 | 5723 5824 5930 | 7.04 7.48 7.94 | 5805 5903 6007 | 7.32 7.76 8.23 | 5886 5982 6083 | 7.60 8.05 8.52 | 5966 6060 6159 | 7.89 8.34 8.82 | 6046 6137 6234 | 8.18 8.63 9.12 |

| 2926 3053 3180 | 4600 4800 5000 | 5664 5793 5925 | 6.98 7.45 7.96 | 5740 5866 5996 | 7.26 7.75 8.26 | 5816 5940 6067 | 7.55 8.05 8.57 | 5892 6013 6138 | 7.84 8.35 8.88 | 5967 6085 6208 | 8.14 8.65 9.19 | 6041 6157 6278 | 8.43 8.95 9.50 | 6116 6229 6348 | 8.73 9.26 9.81 | 6189 6301 6417 | 9.03 9.57 10.13 | 6263 6372 6486 | 9.33 9.88 10.45 | 6336 6443 6555 | 9.64 10.19 10.77 |

| 3307 3434 | 5200 5400 | 6062 6202 | 8.49 9.06 | 6130 6268 | 8.80 9.38 | 6199 6334 | 9.12 9.70 | 6267 6400 | 9.44 10.03 | 6335 6466 | 9.76 10.35 | 6403 6531 | 10.08 10.68 | 6470 6596 | 10.40 11.02 | 6537 6662 | 10.73 11.35 | 6604 6727 | 11.05 11.69 | 6671 6791 | 11.38 12.03 |

Performance certified is for installation type B - free inlet, ducted outlet. Centrifugal Power Fixed Fan.

Class I

Power Rating (BHP) does not include transmission losses (Centrifugal Power Fixed Fan). Performance ratings do not include the effects of appurtenances (accessories).

| Class II | Class III | Class IV |

|---|

6 6 6 6 6

ARRANGEMENT 1-SWSI-CLASS I & II

CENTRIFUGAL POWER FIXED FAN TABLES

| MODEL | WHL. |

|

SHAFT EXT. |

|

TH, DB, BH, UB STRAIGHT DISCH. | BAU, TAU, TAD, BAD ANGULAR DISCH. |

|

|||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NO. | DIA. |

|

DIA. | KEYWAY | A | B | C | D | E | F | H | J | K | L | H | J | K | L | M | N | P | Q | R | X |

| BI105 | 10-1/2 | CLASS I | 3/4 | 3/16 X 3/32 X 1-3/4 | 12-7/8 | 13 | 11-3/4 | 8 | 14-1/4 | 10-3/4 | 7-7/8 | 6-3/4 | 9-1/8 | 8-1/16 | 13-1/4 | 8-7/8 | 9-5/8 | 7-1/8 | 19-5/8 | 6 | 12-7/8 | - | - | 14 |

| BI105 | 10-1/2 | CLASS II | 1 | 1/4 X 1/8 X 2-1/2 | 12-7/8 | 13 | 11-3/4 | 8 | 14-1/4 | 10-3/4 | 7-7/8 | 6-3/4 | 9-1/8 | 8-1/16 | 13-1/4 | 8-7/8 | 9-5/8 | 7-1/8 | 20-3/4 | 6 | 12-7/8 | - | - | 14 |

CENTRIFUGAL POWER FIXED FAN TABLES

Note: Letters “C” and “D” are outside housing dimensions.

7

NIS-CO BLOWERS “Acoustafoil” PERFORMANCE TABLES (CENTRIFUGAL POWER FIXED FAN)

BI122-1 TIP SPEED(FPM)=3.207xRPM OUTLET(.858Sq.Ft. Inside) MAX.HP=.1009(RPM/1000)3 13 1/4"x9 5/8" Outside MAX.RPM

SINGLE-WIDTH CL.1 2978WHEEL DIAMETER=12 1/4 INLET (.921 Sq.Ft. Inside) CL.2 388313 1/4" Dia. Outside CL.3 4897

CENTRIFUGAL POWER FIXED FAN TABLES

| VOL | VEL | .25 SP | .5 SP | .75 SP | 1 SP | 1.25 SP | 1.5 SP | 2SP | 2.5 SP | 3SP | 3.5 SP | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CFM | FPM | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP |

| 686 772 858 | 800 900 1000 | 756 804 856 | 0.04 0.05 0.06 | 955 981 1015 | 0.08 0.09 0.10 | -1155 1174 | -0.13 0.15 | --1328 | --0.20 | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- |

| 944 1030 1115 | 1100 1200 1300 | 911 968 1025 | 0.08 0.09 0.11 | 1056 1101 1151 | 0.12 0.13 0.15 | 1201 1234 1273 | 0.16 0.18 0.20 | 1344 1367 1396 | 0.22 0.24 0.26 | 1482 1497 1518 | 0.28 0.30 0.32 | -1623 1638 | -0.36 0.39 | --- | --- | --- | --- | --- | --- | --- | --- |

| 1201 1287 1373 | 1400 1500 1600 | 1084 1143 1204 | 0.13 0.15 0.17 | 1203 1258 1313 | 0.18 0.20 0.23 | 1317 1364 1414 | 0.23 0.25 0.28 | 1431 1470 1513 | 0.28 0.31 0.34 | 1545 1576 1613 | 0.34 0.37 0.41 | 1657 1683 1713 | 0.41 0.44 0.48 | 1876 1891 1910 | 0.56 0.59 0.63 | -2090 2102 | -0.76 0.80 | --- | --- | --- | --- |

| 1459 1544 1630 | 1700 1800 1900 | 1266 1328 1392 | 0.20 0.23 0.26 | 1370 1428 1486 | 0.26 0.29 0.32 | 1466 1520 1575 | 0.32 0.35 0.39 | 1559 1608 1660 | 0.38 0.42 0.46 | 1653 1696 1743 | 0.44 0.48 0.53 | 1747 1785 1827 | 0.51 0.55 0.60 | 1934 1963 1995 | 0.67 0.71 0.76 | 2118 2138 2162 | 0.84 0.89 0.93 | 2296 2310 2327 | 1.03 1.07 1.13 | -2476 2488 | -1.28 1.33 |

| 1716 1802 1888 | 2000 2100 2200 | 1456 1520 1583 | 0.30 0.34 0.38 | 1545 1604 1664 | 0.36 0.40 0.45 | 1631 1688 1746 | 0.43 0.48 0.53 | 1713 1767 1822 | 0.50 0.55 0.61 | 1792 1843 1895 | 0.58 0.63 0.68 | 1871 1918 1967 | 0.65 0.70 0.76 | 2031 2070 2112 | 0.81 0.87 0.93 | 2190 2222 2257 | 0.99 1.04 1.11 | 2349 2374 2402 | 1.18 1.24 1.30 | 2504 2523 2546 | 1.39 1.45 1.51 |

| 1973 2059 2231 | 2300 2400 2600 | 1647 1711 1839 | 0.43 0.48 0.59 | 1725 1787 1913 | 0.50 0.55 0.67 | 1804 1863 1982 | 0.58 0.64 0.76 | 1879 1935 2051 | 0.66 0.72 0.85 | 1949 2004 2116 | 0.74 0.81 0.95 | 2018 2071 2179 | 0.83 0.89 1.04 | 2156 2203 2302 | 0.99 1.07 1.22 | 2295 2336 2424 | 1.18 1.25 1.41 | 2434 2469 2546 | 1.37 1.45 1.62 | 2573 2602 2669 | 1.58 1.66 1.83 |

| 2402 2574 2746 | 2800 3000 3200 | 1970 2104 2238 | 0.72 0.88 1.06 | 2040 2168 2296 | 0.82 0.98 1.15 | 2103 2227 2353 | 0.90 1.07 1.25 | 2168 2287 2408 | 1.00 1.17 1.36 | 2231 2347 2465 | 1.10 1.28 1.47 | 2291 2405 2521 | 1.20 1.38 1.58 | 2407 2515 2627 | 1.40 1.60 1.81 | 2520 2622 2728 | 1.60 1.81 2.04 | 2633 2727 2827 | 1.81 2.03 2.27 | 2747 2833 2926 | 2.03 2.25 2.50 |

| 2917 | 3400 | 2369 | 1.25 | 2423 | 1.35 | 2480 | 1.47 | 2531 | 1.57 | 2584 | 1.69 | 2638 | 1.81 | 2740 | 2.05 | 2838 | 2.29 | 2932 | 2.53 | 3025 | 2.77 |

| VOL | VEL | 4SP | 4.5 SP | 5SP | 5.5 SP | 6SP | 6.5 SP | 7SP | 7.5 SP | 8SP | 8.5 SP | ||||||||||

| CFM | FPM | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP |

| 1802 1888 | 2100 2200 | 2670 2688 | 1.67 1.74 | 2814 2828 | 1.90 1.97 | -2965 | -2.21 | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- |

| 1973 2059 2231 | 2300 2400 2600 | 2710 2734 2792 | 1.81 1.89 2.06 | 2845 2865 2915 | 2.05 2.13 2.30 | 2978 | 2.29 | 3108 | 2.55 | - | - | - | - | - | - | - | - | - | - | - | - |

| 2995 3036 | 2.38 2.56 | 3122 3157 | 2.63 2.82 | 3246 3275 | 2.90 3.09 | -3392 | -3.37 | -3507 | -3.67 | -3621 | -3.97 | -- | -- | -- | -- | ||||||

| 2402 2574 2746 | 2800 3000 3200 | 2861 2939 | 2.26 2.48 | 2976 | 2.50 | 3089 | 2.76 | 3203 | 3.03 | 3315 | 3.31 | 3426 | 3.59 | 3536 | 3.89 | 3645 | 4.19 | 3752 | 4.50 | 3858 | 4.82 |

| 3046 | 2.73 | 3153 | 2.99 | 3259 | 3.26 | 3365 | 3.54 | 3471 | 3.83 | 3575 | 4.13 | 3679 | 4.44 | 3782 | 4.76 | 3883 | 5.08 | ||||

| 3026 | 2.74 | 3125 | 2.99 | 3225 | 3.25 | 3325 | 3.52 | 3425 | 3.81 | 3525 | 4.10 | 3624 | 4.40 | 3723 | 4.72 | 3820 | 5.04 | 3918 | 5.37 | ||

| 2917 3089 3260 | 3400 3600 3800 | 3118 3216 3319 | 3.02 3.33 3.67 | 3212 3304 3402 | 3.28 3.60 3.94 | 3305 3393 3486 | 3.54 3.87 4.22 | 3399 3481 3569 | 3.82 4.14 4.51 | 3494 3570 3653 | 4.10 4.43 4.80 | 3588 3659 3737 | 4.40 4.73 5.10 | 3682 3748 3821 | 4.71 5.04 5.41 | 3775 3837 3906 | 5.02 5.36 5.73 | 3869 3925 3990 | 5.35 5.69 6.06 | 3961 4014 4074 | 5.68 6.02 6.40 |

| 3432 3604 3775 | 4000 4200 4400 | 3425 3534 3645 | 4.04 4.43 4.85 | 3504 3610 3718 | 4.32 4.73 5.16 | 3584 3686 3791 | 4.61 5.03 5.47 | 3663 3761 3863 | 4.90 5.33 5.79 | 3742 3836 3935 | 5.20 5.63 6.10 | 3822 3912 4007 | 5.50 5.95 6.42 | 3902 3988 4079 | 5.82 6.26 6.75 | 3981 4064 4151 | 6.14 6.59 7.08 | 4061 4140 4223 | 6.47 6.93 7.42 | 4141 4216 4296 | 6.81 7.27 7.77 |

| 3947 4118 4290 | 4600 4800 5000 | 3757 3871 3986 | 5.30 5.78 6.29 | 3828 3940 4054 | 5.63 6.12 6.65 | 3899 4008 4120 | 5.95 6.46 7.00 | 3968 4075 4185 | 6.28 6.80 7.36 | 4037 4142 4249 | 6.60 7.14 7.71 | 4106 4208 4313 | 6.93 7.48 8.06 | 4175 4274 4377 | 7.27 7.82 8.42 | 4243 4340 4440 | 7.61 8.17 8.78 | 4312 4406 4503 | 7.95 8.52 9.14 | 4382 4472 4567 | 8.30 8.88 9.50 |

| 4462 4633 | 5200 5400 | 4101 4218 | 6.83 7.40 | 4168 4283 | 7.20 7.79 | 4233 4347 | 7.58 8.18 | 4296 4409 | 7.94 8.57 | 4359 4470 | 8.31 8.95 | 4421 4530 | 8.68 9.33 | 4482 4590 | 9.05 9.71 | 4543 4649 | 9.42 10.09 | 4604 4707 | 9.79 10.48 | 4665 4766 | 10.16 10.86 |

| VOL CFM | VEL FPM | 9 SP | 9.5 SP | 10 SP | 10.5 SP | 11 SP | 11.5SP | 12SP | 12.5SP | 13SP | 13.5 SP | ||||||||||

| RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | RPM | BHP | RPM | RPM | RPM | BHP | RPM | BHP | ||

| 2574 2746 | 3000 3200 | 3984 4014 | 5.41 5.71 | 4083 4110 | 5.75 6.05 | 4181 4204 | 6.10 6.40 | -4298 | -6.76 | -4390 | -7.13 | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- |

| 2917 3089 3260 | 3400 3600 3800 | 4054 4102 4158 | 6.02 6.37 6.75 | 4145 4189 4241 | 6.37 6.72 7.11 | 4236 4276 4325 | 6.73 7.08 7.47 | 4326 4363 4408 | 7.09 7.45 7.84 | 4416 4449 4491 | 7.46 7.83 8.22 | 4504 4534 4573 | 7.84 8.21 8.61 | 4592 4619 4654 | 8.22 8.59 9.00 | 4679 4703 4736 | 8.61 8.99 9.40 | -4787 4816 | -9.39 9.80 | -4870 4897 | -9.80 10.22 |

| 3432 3604 3775 | 4000 4200 4400 | 4221 | 7.17 | 4301 | 7.52 | 4381 | 7.89 | 4460 | 8.27 | 4540 | 8.65 | 4619 | 9.04 | 4697 | 9.44 | 4776 | 9.84 | 4853 | 10.25 | 4931 | 10.67 |

| 4292 4369 | 7.62 8.12 | 4368 4441 | 7.98 8.48 | 4444 4514 | 8.35 8.85 | 4520 4587 | 8.73 9.23 | 4596 4660 | 9.12 9.62 | 4672 4732 | 9.51 10.02 | 4747 4805 | 9.91 10.42 | 4823 4877 | 10.32 10.83 | 4898 4949 | 10.73 11.25 | 4972 5021 | 11.15 11.68 | ||

| 3947 4118 4290 | 4600 4800 5000 | 4451 4538 4630 | 8.66 9.25 9.87 | 4520 4605 4694 | 9.03 9.62 10.25 | 4590 4671 4757 | 9.40 9.99 10.63 | 4659 4738 4821 | 9.78 10.38 11.02 | 4729 4804 4885 | 10.17 10.77 11.41 | 4799 4871 4949 | 10.57 11.17 11.82 | 4868 4938 5013 | 10.98 11.58 12.23 | 4938 5004 5077 | 11.39 11.99 12.64 | 5007 5071 5141 | 11.81 12.42 13.07 | 5076 5138 5205 | 12.24 12.85 13.50 |

| 4462 4633 | 5200 5400 | 4726 4825 | 10.54 11.25 | 4787 4883 | 10.92 11.64 | 4848 4942 | 11.31 12.04 | 4909 5001 | 11.71 12.44 | 4970 5060 | 12.11 12.84 | 5031 5119 | 12.51 13.25 | 5093 5178 | 12.92 13.67 | 5154 5237 | 13.34 14.10 | 5216 5296 | 13.77 14.52 | 5277 5355 | 14.20 14.96 |

Performance certified is for installation type B -free inlet, ducted outlet. Power Rating (BHP) does not include transmission losses. Class I Performance ratings do not include the effects of appurtenances (accessories).

CENTRIFUGAL POWER FIXED FAN TABLES

| Class III | Class II | Class IV |

|---|

8

ARRANGEMENT 1 & 9-SWSI-CLASS I & II

CENTRIFUGAL POWER FIXED FAN TABLES

| MODEL | WHL. |

|

SHAFT EXT. |

|

TH, DB, BH, UB STRAIGHT DISCH. | BAU, TAU, TAD, BAD ANGULAR DISCH. |

|

|||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NO. | DIA. |

|

DIA. | KEYWAY | A | B | C | D | E | F | H | J | K | L | H | J | K | L | M | N | P | Q | R | X |

| BI122 | 12-1/4 | CLASS I | 1 | 1/4 X 1/8 X 3-1/2 | 16-3/8 | 13-1/2 | 13-1/4 | 9-5/8 | 13-1/2 | 14-3/4 | 10-1/8 | 8-1/2 | 11-1/2 | 10-1/2 | 16-5/8 | 10-3/4 | 12-1/2 | 9-1/8 | 23-7/8 | 6-3/8 | 13-1/4 | 11-1/4 | 12-3/4 | 17 |

| BI122 | 12-1/4 | CLASS II | 1-3/16 | 1/4 X 1/8 X 3-1/2 | 16-3/8 | 13-1/2 | 13-1/4 | 9-5/8 | 15-1/2 | 14-3/4 | 10-1/8 | 8-1/2 | 11-1/2 | 10-1/2 | 16-5/8 | 10-3/4 | 12-1/2 | 9-1/8 | 25-7/8 | 6-3/8 | 13-1/4 | 11-1/4 | 12-3/4 | 17 |

CENTRIFUGAL POWER FIXED FAN TABLES

Note: Letters “C” and “D” are outside housing dimensions.

9

ARRANGEMENT 1 & 9-SWSI-CLASS I & II

| MODEL | WHL. |

|

SHAFT EXT. |

|

TH, DB, BH, UB STRAIGHT DISCH. | BAU, TAU, TAD, BAD ANGULAR DISCH. |

|

|||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NO. | DIA. |

|

DIA. | KEYWAY | A | B | C | D | E | F | H | J | K | L | H | J | K | L | M | N | P | Q | R | X |

| BI150 | 15 | CLASS I | 1 | 1/4 X 1/8 X 3-1/2 | 19-1/4 | 15-1/2 | 16-1/4 | 11-3/4 | 15-1/2 | 17-5/8 | 12-3/8 | 10-3/8 | 14-1/8 | 12-3/8 | 20-1/8 | 13-1/4 | 15-1/4 | 11-1/8 | 26-7/8 | 7-1/2 | 16-1/8 | 13-3/8 | 14-7/8 | 17-7/8 |

| BI150 | 15 | CLASS II | 1-3/16 | 1/4 X 1/8 X 3-1/2 | 19-1/4 | 15-1/2 | 16-1/4 | 11-3/4 | 15-1/2 | 17-5/8 | 12-3/8 | 10-3/8 | 14-1/8 | 12-3/8 | 20-1/8 | 13-1/4 | 15-1/4 | 11-1/8 | 27 | 7-1/2 | 16-1/8 | 13-3/8 | 14-7/8 | 17-7/8 |

CENTRIFUGAL POWER FIXED FAN TABLES

Note: Letters “C” and “D” are outside housing dimensions.

13

ARRANGEMENT 1 & 9-SWSI-CLASS I & II

| MODEL | WHL. |

|

SHAFT EXT. |

|

TH, DB, BH, UB STRAIGHT DISCH. | BAU, TAU, TAD, BAD ANGULAR DISCH. |

|

|||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NO. | DIA. |

|

DIA. | KEYWAY | A | B | C | D | E | F | H | J | K | L | H | J | K | L | M | N | P | Q | R | X |

| BI165 | 16-1/2 | CLASS I | 1 | 1/4 X 1/8 X 3-1/2 | 21-3/8 | 15 | 17-3/4 | 13 | 15-1/2 | 19-3/4 | 13-5/8 | 11-3/8 | 15-1/2 | 13-3/8 | 21-7/8 | 14-5/8 | 16-3/4 | 12-1/4 | 27-1/2 | 8-1/2 | 17-7/8 | 14-1/2 | 17 | 19-1/2 |

| BI165 | 16-1/2 | CLASS II | 1-3/16 | 1/4 X 1/8 X 4 | 21-3/8 | 21 | 17-3/4 | 13 | 21-1/2 | 19-3/4 | 13-5/8 | 11-3/8 | 15-1/2 | 13-3/8 | 21-7/8 | 14-5/8 | 16-3/4 | 12-1/4 | 34-1/8 | 8-1/2 | 17-7/8 | 14-1/2 | 17 | 19-1/2 |

CENTRIFUGAL POWER FIXED FAN TABLES

Note: Letters “C” and “D” are outside housing dimensions.

15

ARRANGEMENT 1 & 9-SWSI-CLASS I & II

| MODEL | WHL. |

|

SHAFT EXT. |

|

TH, DB, BH, UB STRAIGHT DISCH. | BAU, TAU, TAD, BAD ANGULAR DISCH. |

|

|||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NO. | DIA. |

|

DIA. | KEYWAY | A | B | C | D | E | F | H | J | K | L | H | J | K | L | M | N | P | Q | R | X |

| BI182 | 18-1/4 | CLASS I | 1-3/16 | 1/4 X 1/8 X 3-1/2 | 23-1/8 | 17 | 19-5/8 | 14-1/4 | 17-1/2 | 21-1/2 | 15 | 12-5/8 | 17-1/8 | 14-5/8 | 24-1/8 | 16 | 18-1/2 | 13-5/8 | 30-5/8 | 9-1/8 | 19-5/8 | 15-3/4 | 18-1/4 | 21-7/8 |

| BI182 | 18-1/4 | CLASS II | 1-7/16 | 3/8 X 3/16 X 4 | 23-1/8 | 21 | 19-5/8 | 14-1/4 | 21-1/2 | 21-1/2 | 15 | 12-5/8 | 17-1/2 | 14-5/8 | 24-1/8 | 16 | 18-1/2 | 13-5/8 | 34-5/8 | 9-1/8 | 19-5/8 | 15-3/4 | 18-1/4 | 21-7/8 |

Note: Letters “C” and “D” are outside housing dimensions.

17

ARRANGEMENT 1 & 9-SWSI-CLASS I & II

| MODEL | WHL. |

|

SHAFT EXT. |

|

TH, DB, BH, UB STRAIGHT DISCH. | BAU, TAU, TAD, BAD ANGULAR DISCH. |

|

|||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NO. | DIA. |

|

DIA. | KEYWAY | A | B | C | D | E | F | H | J | K | L | H | J | K | L | M | N | P | Q | R | X |

| BI200 | 20 | CLASS I | 1-3/16 | 1/4 X 1/8 X 3-1/2 | 25 | 17 | 21-1/2 | 15-7/8 | 17 | 23-3/8 | 16-1/2 | 13-3/4 | 18-3/4 | 15-3/4 | 26-3/8 | 17-5/8 | 20-3/8 | 14-7/8 | 31-1/2 | 10 | 21-1/2 | 17-7/8 | 20-1/8 | 23-3/4 |

| BI200 | 20 | CLASS II | 1-7/16 | 3/8 X 3/16 X 4 | 25 | 21 | 21-1/2 | 15-7/8 | 21 | 23-3/8 | 16-1/2 | 13-3/4 | 18-3/4 | 15-3/4 | 26-3/8 | 17-5/8 | 20-3/8 | 14-7/8 | 35-5/8 | 10 | 21-1/2 | 17-7/8 | 20-1/8 | 23-3/4 |

Note: Letters “C” and “D” are outside housing dimensions.

19

NIS-CO BLOWERS “Acoustafoil” PERFORMANCE TABLES

BI222-1 TIP SPEED(FPM)=5.825xRPM OUTLET(2.827 Sq.Ft. Inside) MAX.HP=1.8739 (RPM/1000)3 24" x17 3/8" Outside MAX.RPM

SINGLE-WIDTH

CL.1 1661 WHEEL DIAMETER=22 1/4" INLET (3.015 Sq.Ft. Inside)

ARRANGEMENT 1 & 9-SWSI-CLASS I & II

| MODEL | WHL. |

|

SHAFT EXT. |

|

TH, DB, BH, UB STRAIGHT DISCH. | BAU, TAU, TAD, BAD ANGULAR DISCH. |

|

|||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NO. | DIA. |

|

DIA. | KEYWAY | A | B | C | D | E | F | H | J | K | L | H | J | K | L | M | N | P | Q | R | X |

| BI222 | 22-1/4 | CLASS I | 1-3/16 | 1/4 X 1/8 X 3-1/2 | 27-3/8 | 16-1/2 | 24 | 17-3/8 | 17 | 25-3/4 | 18-1/4 | 15-1/4 | 20-7/8 | 17-1/4 | 29 | 19-1/2 | 22-5/8 | 16-1/2 | 32-3/4 | 10-5/8 | 23-7/8 | 19-3/8 | 22-5/8 | 26-1/8 |

| BI222 | 22-1/4 | CLASS II | 1-11/16 | 3/8 X 3/16 X 4 | 27-3/8 | 22-1/2 | 24 | 17-3/8 | 23 | 25-3/4 | 18-1/4 | 15-1/4 | 20-7/8 | 17-1/4 | 29 | 19-1/2 | 22-5/8 | 16-1/2 | 38-3/8 | 10-5/8 | 23-7/8 | 19-3/8 | 22-5/8 | 26-1/8 |

Note: Letters “C” and “D” are outside housing dimensions.

21

ARRANGEMENT 1 & 9-SWSI-CLASS I & II

| MODEL | WHL. |

|

SHAFT EXT. |

|

TH, DB, BH, UB STRAIGHT DISCH. | BAU, TAU, TAD, BAD ANGULAR DISCH. |

|

|||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NO. | DIA. |

|

DIA. | KEYWAY | A | B | C | D | E | F | H | J | K | L | H | J | K | L | M | N | P | Q | R | X |

| BI245 | 24-1/2 | CLASS I | 1-7/16 | 3/8 X 3/16 X 3-1/2 | 30-1/4 | 17-7/8 | 26-1/4 | 19-1/4 | 18-1/8 | 23-5/8 | 20-1/8 | 16-7/8 | 23 | 19-7/8 | 32-1/2 | 21-1/2 | 24-7/8 | 18-1/4 | 34-1/2 | 11-3/4 | 26-3/8 | 21-1/4 | 24-1/2 | 27-3/4 |

| BI245 | 24-1/2 | CLASS II | 1-11/16 | 3/8 X 3/16 X 5 | 30-1/4 | 22-1/2 | 26-1/4 | 19-1/4 | 22-3/4 | 23-5/8 | 20-1/8 | 16-7/8 | 23 | 19-7/8 | 32-1/2 | 21-1/2 | 24-7/8 | 18-1/4 | 40-1/2 | 11-3/4 | 26-3/8 | 21-1/4 | 24-1/2 | 27-3/4 |

Note: Letters “C” and “D” are outside housing dimensions.

23

NIS-CO BLOWERS “Acoustafoil” PERFORMANCE TABLES

BI122-2 TIPSPEED(FPM)=3.207xRPM OUTLET(1.548Sq.Ft.Inside) MAX.HP=1.849(RPM/1000)3 13 1/4" x17 1/4" Outside MAX.RPM

DOUBLE-WIDTH

CL.1 3045 WHEEL DIAMETER=12 1/4" INLET (1.842 Sq.Ft. Inside) CL2. 3971

ARRANGEMENT 3-DWDI-CLASS I & II

| MODEL | WHL. | SHAFT EXT. |

|

SHAFT EXT. |

|

|||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| STRAIGHT DISCH. TH, DB, BH, UB | BAU, TAU, TAD, BAD ANGULAR DISCH. | CLASS I | CLASS II | |||||||||||||||||||||

| NO. | DIA. | DIA. | KEYWAY | DIA. | KEYWAY | |||||||||||||||||||

|

|

CLASS I |

|

CLASS II | A | C | D | F | H | J | K | L | H | J | K | L | M | M | N | P | Q | R | X | ||

| BI122 | 12-1/4 | 1-3/16 | 1/4 X 1/8 X 3-1/2 | 1-7/16 | 3/8 X 3/16 X 3-1/2 | 16-3/8 | 13-1/4 | 17-1/4 | 14-3/4 | 10-1/8 | 8-1/2 | 11-1/2 | 10-1/2 | 16-5/8 | 10-3/4 | 12-1/2 | 9-1/8 | 16 | 16 | 10-1/4 | 13-1/4 | 18-3/4 | 20-1/4 | 17 |

Note: Letters “C” and “D” are outside housing dimensions.

25

ARRANGEMENT 3-DWDI-CLASS I & II

| MODEL | WHL. | SHAFT EXT. |

|

SHAFT EXT. |

|

|||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| STRAIGHT DISCH. TH, DB, BH, UB | BAU, TAU, TAD, BAD ANGULAR DISCH. | CLASS I | CLASS II | |||||||||||||||||||||

| NO. | DIA. | DIA. | KEYWAY | DIA. | KEYWAY | |||||||||||||||||||

|

|

CLASS I |

|

CLASS II | A | C | D | F | H | J | K | L | H | J | K | L | M | M | N | P | Q | R | X | ||

| BI135 | 13-1/2 | 1-3/16 | 1/4 X 1/8 X 3-1/2 | 1-7/16 | 3/8 X 3/16 X 3-1/2 | 17-5/8 | 14-5/8 | 19 | 16 | 11-1/8 | 9-3/8 | 12-5/8 | 11-3/8 | 18-1/4 | 11-7/8 | 13-3/4 | 10 | 16-3/4 | 16-3/4 | 11 | 14-1/2 | 20-1/2 | 22 | 17 |

Note: Letters “C” and “D” are outside housing dimensions.

27

ARRANGEMENT 3-DWDI-CLASS I & II

| MODEL | WHL. | SHAFT EXT. |

|

SHAFT EXT. |

|

|||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| STRAIGHT DISCH. TH, DB, BH, UB | BAU, TAU, TAD, BAD ANGULAR DISCH. | CLASS I | CLASS II | |||||||||||||||||||||

| NO. | DIA. | DIA. | KEYWAY | DIA. | KEYWAY | |||||||||||||||||||

|

|

CLASS I | CLASS II | A | C | D | F | H | J | K | L | H | J | K | L | M | M | N | P | Q | R | X | |||

| BI150 | 15 | 1-7/16 | 3/8 X 3/16 X 3-1/2 | 1-11/16 | 3/8 X 3/16 X 4 | 19-1/4 | 16-1/4 | 20-7/8 | 17-5/8 | 12-3/8 | 10-3/8 | 14-1/8 | 12-3/8 | 20-1/8 | 13-1/4 | 15-1/4 | 11-1/8 | 17-3/4 | 18-1/2 | 12 | 16-1/8 | 22-3/8 | 23-7/8 | 17-7/8 |

Note: Letters “C” and “D” are outside housing dimensions.

29

ARRANGEMENT 3-DWDI-CLASS I & II

| MODEL | WHL. | SHAFT EXT. |

|

SHAFT EXT. |

|

|||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| STRAIGHT DISCH. TH,DB, BH,UB | BAU,TAU,TAD,BAD ANGULAR DISCH. | CLASS I | CLASS II | |||||||||||||||||||||

| NO. | DIA. | DIA. | KEYWAY | DIA. | KEYWAY | |||||||||||||||||||

|

|

CLASS I | CLASS II | A | C | D | F | H | J | K | L | H | J | K | L | M | M | N | P | Q | R | X | |||

| BI165 | 16-1/2 | 1-7/16 | 3/8 X 3/16 X 3-1/2 | 1-15/16 | 1/2 X 1/4 X 6 | 21-3/8 | 17-3/4 | 23-1/8 | 19-3/4 | 13-5/8 | 11-3/8 | 15-1/2 | 13-3/8 | 21-7/8 | 14-5/8 | 16-3/4 | 12-1/4 | 18-1/2 | 21-3/4 | 13-5/8 | 17-7/8 | 24-5/8 | 27-1/8 | 19-1/2 |

Note: Letters “C” and “D” are outside housing dimensions.

31

ARRANGEMENT 3-DWDI-CLASS I & II

| MODEL | WHL. | SHAFT EXT. |

|

SHAFT EXT. |

|

|||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

STRAIGHT DISCH. TH,DB, BH,UB | BAU,TAU,TAD, BAD ANGULAR DISCH. | CLASS I | CLASS II | ||||||||||||||||||||

| NO. | DIA. | DIA. | KEYWAY | DIA. | KEYWAY | |||||||||||||||||||

|

|

CLASS I | CLASS II | A | C | D | F | H | J | K | L | H | J | K | L | M | M | N | P | Q | R | X | |||

| BI182 | 18-1/4 | 1-11/16 | 3/8 X 3/16 X 3-1/2 | 1-15/16 | 1/2 X 1/4 X 6 | 23-1/8 | 19-5/8 | 25-1/2 | 21-1/2 | 15 | 12-5/8 | 17-1/8 | 14-5/8 | 24-1/8 | 16 | 18-1/2 | 13-5/8 | 19-7/8 | 23 | 14-3/4 | 19-5/8 | 27 | 29-1/2 | 21-7/8 |

Note: Letters “C” and “D” are outside housing dimensions.

33

ARRANGEMENT 3-DWDI-CLASS I & II

| MODEL | WHL. | SHAFT EXT. |

|

SHAFT EXT. |

|

|||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| STRAIGHT DISCH. TH, DB, BH, UB | BAU, TAU, TAD, BAD ANGULAR DISCH. | CLASS I | CLASS II | |||||||||||||||||||||

| NO. | DIA. | DIA. | KEYWAY | DIA. | KEYWAY | |||||||||||||||||||

|

|

CLASS I | CLASS II | A | C | D | F | H | J | K | L | H | J | K | L | M | M | N | P | Q | R | X | |||

| BI200 | 20 | 1-11/16 | 3/8 X 3/16 X 4 | 2-3/16 | 1/2 X 1/4 X 6 | 25 | 21-1/2 | 28-3/8 | 23-3/8 | 16-1/2 | 13-3/4 | 18-3/4 | 15-3/4 | 26-3/8 | 17-5/8 | 20-3/8 | 14-7/8 | 21-3/4 | 24-3/4 | 16-1/4 | 21-1/2 | 30-3/8 | 32-3/8 | 23-3/4 |

Note: Letters “C” and “D” are outside housing dimensions.

35

ARRANGEMENT 3-DWDI-CLASS I & II

| MODEL | WHL. | SHAFT EXT. |

|

SHAFT EXT. |

|

|||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| STRAIGHT DISCH. TH,DB, BH,UB | BAU,TAU,TAD,BAD ANGULAR DISCH. | CLASS I | CLASS II | |||||||||||||||||||||

| NO. | DIA. | DIA. | KEYWAY | DIA. | KEYWAY | |||||||||||||||||||

|

|

CLASS I | CLASS II | A | C | D | F | H | J | K | L | H | J | K | L | M | M | N | P | Q | R | X | |||

| BI222 | 22-1/4 | 1-15/16 | 1/2 X 1/4 X 4 | 2-3/16 | 1/2 X 1/4 X 6 | 27-3/8 | 24 | 31 | 25-3/4 | 18-1/4 | 15-1/4 | 20-7/8 | 17-1/4 | 29 | 19-1/2 | 22-5/8 | 16-1/2 | 23-3/8 | 26 | 18 | 23-7/8 | 33 | 36 | 26-1/8 |

Note: Letters “C” and “D” are outside housing dimensions.

37

NIS-CO BLOWERS

ARRANGEMENT 3-DWDI-CLASS I & II

| MODEL | WHL. | SHAFT EXT. |

|

SHAFT EXT. |

|

|||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| STRAIGHT DISCH. TH,DB, BH,UB | BAU,TAU,TAD, BAD ANGULAR DISCH. | CLASS I | CLASS II | |||||||||||||||||||||

| NO. | DIA. | DIA. | KEYWAY | DIA. | KEYWAY | |||||||||||||||||||

|

|

CLASS I | CLASS II | A | C | D | F | H | J | K | L | H | J | K | L | M | M | N | P | Q | R | X | |||

| BI245 | 24-1/2 | 1-15/16 | 1/2 X 1/4 X 6 | 2-7/16 | 5/8 X 5/16 X 6 | 30-1/4 | 26-1/4 | 34-1/2 | 23-5/8 | 20-1/8 | 16-7/8 | 23 | 19-7/8 | 32-1/2 | 21-1/2 | 24-7/8 | 18-1/4 | 26-5/8 | 27-7/8 | 19-1/4 | 26-3/8 | 36-1/2 | 39-1/2 | 27-3/4 |

Note: Letters “C” and “D” are outside housing dimensions.

39

Contact NIS-CO today to find out more about our full line of world class backward inclined blowers to meet all of your industrial blower fan needs. Our backward inclined blowers are used in both commercial and industrial applications and are used all over Canada and the United States. Canada Blower Industrial Blowers and Large Industrial Fans come in both Direct Drive Blower and Belt Drive Blower configurations. You can also choose between forward curve blowers and backward inclined blowers, depending on your needs. We also carry a range of centrifugal blower fans which are high rated and high temperature blowers. We also carry a wide range of propeller fans, plenum fans, large industrial fans which can come in both belt drive and direct drive configurations.